Testing offshore piles in Taiwan

When a wind turbine park was to be built off the coast of Taiwan with traditional jackets with pile foundation, the client wanted a full-scale field test of the pile capacity before final design and installation. NGI was given responsibility for instrumentation and implementation of the pile tests.

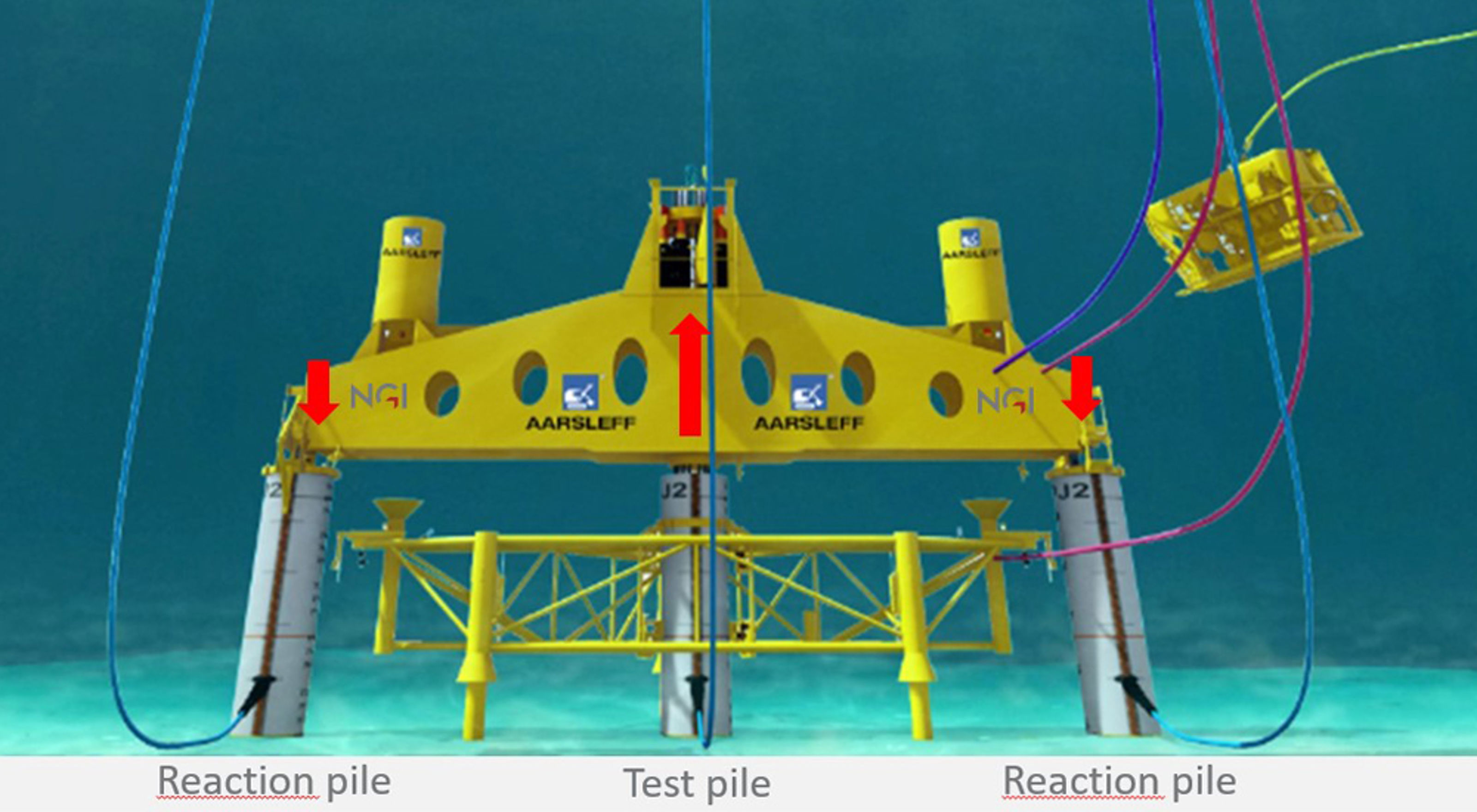

NGI's main task was to design, produce and install an instrumentation system that could record the necessary data to control the pile installation and measure the capacity of the piles. It included instrumentation of piles, and pile frame, load beam and reference frame, which are installations mounted on the seabed where the pile tests were to be performed.

At a water depth of 35 to 40 meters, a total of six piles were installed. Measuring equipment was installed on the 70 to 80 meter long piles, so that NGI could carry out and monitor the results of the pile tests.

Instrumentation and assembly work in many locations

The project was complex, with complicated logistics to many locations around the world. Planning and design of the system for instrumentation was done by NGI's specialists in Oslo.

NGI carried out field work at three locations - Esbjerg in Denmark, Singapore and Taiwan. In addition, the offshore operations were done in two phases - pile installation with logging of measurement data during pile installations. And after about three months of waiting, the actual pile testing was completed.

The piles on the yard in Taiwan

Equipment for installation and testing of the piles (pile frame, load beam and reference frame), was built at a yard in Esbjerg. All parts were instrumented by NGI in Esbjerg before transport to Singapore for reloading to the vessel that was to install the piles on the test field off the coast of Taiwan.

The piles were manufactured at a shipyard in Taiwan and all the sensors and cables were installed by NGI personnel there. A team of six NGIs participated in this assembly work. In total, approx. 360 sensors, consisting of traditional strain gauges, temperature gauges and fibre optic sensors. The work was done inside the piles, which have a diameter of only 1.5 m.

Pictures from instrumentation of the piles at the yard in Taiwan. Top left: Narrow space to mount inside the pile in temperatures of 40 degrees Celsius. Below: Indication of channels for cables for tension flaps and PDA signals (Pile Driving Analyzer) inside the pile. Center: Cable mounting inside the pile. Right: "Umbilical cord" for power and signal cables and their attachment.

In addition to instrumentation of the piles themselves, NGI also delivered advanced measurement systems for the installation frame that were used during pile installation. Measuring equipment was also mounted on the measuring frame (load beam) that was used during the actual load tests of the piles.

Load tests

About 100 days after the piles were penetrated into the seabed, the test piles were subjected to controlled static and cyclic loading. Initially, they were pulled vertically upwards to failure and subsequently subjected to lateral loading to large displacements.

NGI had four people specialists participating in the two main activities offshore Taiwan (installation and pile testing) to ensure that the measurement and data acquisition systems worked properly and registered the data to be measured.

The pile tests were monitored and followed in real time via internet connection by NGI's expert team in Oslo and London and by the client at several locations in Europe. From the other side of the globe, one could thus follow the testing off the coast of Taiwan and provide direct input and directives on the field operations implementation of the experiments.

Data from the field tests were interpreted and the results were then used directly in the final design of the jacket piles for the wind farm off the coast of Taiwan.

Complementary specialist expertise

The project was successful and was carried out according to plan and expectations, and agreed services and results were delivered within a very tight schedule. The results from the pile tests provided valuable information for the safe design of the pile foundations for the first wind farm. The results will also be valuable for the next phases of the wind farm development and can result in significant cost reduction for the foundations.

The project included several technical skills and scientific know-how areas where NGI has specialist expertise. Such as:

- development and use of instrumentation systems and sensors for use offshore under very "rough" filed and environmental conditions

- field work - with installation of sensors and follow-up of pile installation and load tests

- handling very large amounts of measurement data in real time transmitted via the Internet

- data storage and presentation and assessment of test results

- assessment of ground conditions, interpretation of measurement data and geotechnical evaluation.

This was a prerequisite for the successful results in this project.

Karl Henrik Mokkelbost

Senior Specialist Field Testing and Offshore Instrumentation karl.henrik.mokkelbost@ngi.no+47 928 63 592