- NGI /

- Projects /

- SLUDGEFFECT /

- WP2

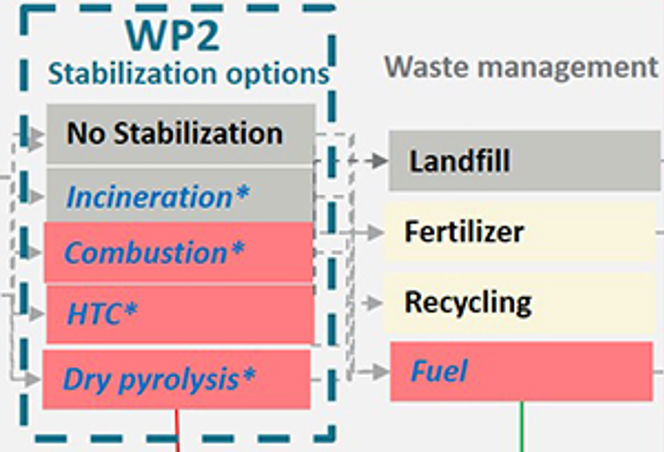

WP2 - Stabilization options

The objective is to quantify how combustion, dry pyrolysis and HTC can remove selected hazardous substances from sludge and plastic; and characterize the hazards and innovation potential of resulting residues for reducing contaminant emissions.

WP2 will test the following novel hypotheses:

- hazardous substances are best removed from sewage sludge after anaerobic biogas generation, followed by carbonization

- the higher the carbonization temperature, the more organic hazardous substances are removed

- the formation of hazardous byproducts (like dioxins), residual heavy metals and odours are the least abundant and/or bioavailable for high temperature (>700 °C) dry pyrolysis.

Task 2.1

The influence of carbonization on hazardous substance concentrations. Representative samples of

a) sewage sludge,

b) digested sewage sludge after anaerobic digestion for biogas production,

c) e-waste plastic, and

d) mixed e-waste and sludge

will be prepared and analysed for the selected contaminants in WP1.

If the concentrations are too small in all samples, these will be added/spiked to selected samples. Then these will be exposed to the following combustion methods (n >=3), and the concentration of hazardous contaminants before and after will be measured.

- Combustion for energy production at 850 °C, recommended for EU waste-to-energy plants

- Dry pyrolysis at 300 °C, 500 °C, 700 °C and 900 °C. This method would yield the most solid material to be used as fertilizer (biochar), with the higher the temperature, the better the sorption and the lesser the bioavailability of contaminants.15 This is preferred for e-waste

- Hydrothermal carbonization (HTC), which generally gives better conversion to material and energy recovery, including nutrient recycling; and requires less energy input than dry pyrolysis; however, for e-waste plastics it produces problematic halogenated byproducts Ref. 11).

After the applications of these methods, the solids and liquids will be separated, a mass balance (change in weight) will be conducted to estimate losses due to volatiles. The solids and liquids will be analysed for the hazardous substances in WP1, along with (halogenated) dioxin generation.

Task 2.2

Influence of carbonization on bioavailable concentrations. Total concentrations are not the best indicator of risk. Some of the residual organics, dioxins and metals may be trapped within the matrix of the carbonized waste products, and therefore are not bioavailable when used as a fertilizer or coal product. This bioavailability of residual organics, dioxins and metals will be measured using passive samplers, as done previously by SLUDGEFFECT researchers (Ref. 7, 13).

Task 2.3

Influence of carbonization on bioavailable nutrient (P-, N- based) concentrations. This will be analyzed on samples using standard analysis CAT method (CaCl2/DTPA), to estimate the effect of carbonization on the solid products nutritional value.

Task 2.4

Odorants. The change in odorants from carbonization will be will be analyzed by a) empirical survey of lab staff before and after carbonization; b) quantifying volatile organic sulfur by exposing a passive sampler (e.g. Radiello®) in a closed chamber with the test material for a set amount of time.

Task 2.5

Carbonization and hazardous substance management. The mass balance model from Task 1.2 will be used to derive the effect of different technologies have on mitigating the total risks and emissions of the analyzed contaminants, to estimate how implementation of these carbonization options will affect Norwegian emissions of hazardous substances from sludge and plastic. Previous emission factors to air, water, and soil from landfilling, combustion and recycling generated from the MILJØFORSK research project WASTEFFECT will assist this assessment.